Centrifugal separation

Fully Automatic Batch Type Centrifuge

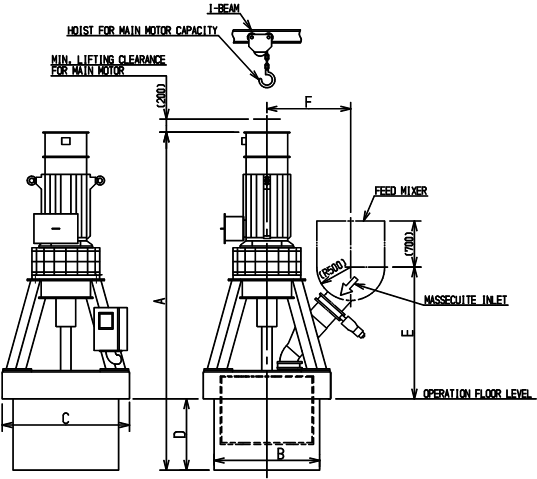

Structure and Principle

This batch-type centrifuge can operate fully automatically all processes of slurry feeding (one cycle), cake washing, dewatering, and crystal discharge, within a single cycle, after settings are made for basket rotations, supply amount, washing time, and other parameters in accordance with the characteristics of the slurry. The centrifuge performs solid-liquid separation by rotating a vertical basket screen with dewatering pores, at high speeds. The bearing unit can be shaken using anti-vibration rubber, while the drive motor can be installed on top of the separator. These features enable large-capacity processing.

Features

Large-capacity basket mountable

Mounting of a large-capacity basket can achieve a centrifugal force of 1,000G or more.

Shortened cycle time

The mounting of a large-capacity motor can shorten the cycle time.

Preventing the leakage of supply liquid and washing water

A basket valve is provided to close the cake outlet, which prevents the leakage of supply liquid to washing water toward the cake.

Preventing crystal cracks

The scraping process prevents crystal cracks, as the basket scrapes crystals with a scraper.

Energy saving

When the rotational speed is lowered from dewatering rotation to scraping rotation within the same cycle, the electricity generated in the separator is transferred to the power supply. In addition, the installed high-efficiency (permanent magnet) motor helps achieve energy saving.